Our testers are fast accurate and easy to use. 73 Functional test- The following test shall be conducted on each harness assembly manufactured to this specification prior to submission for GSFC inspection and acceptance.

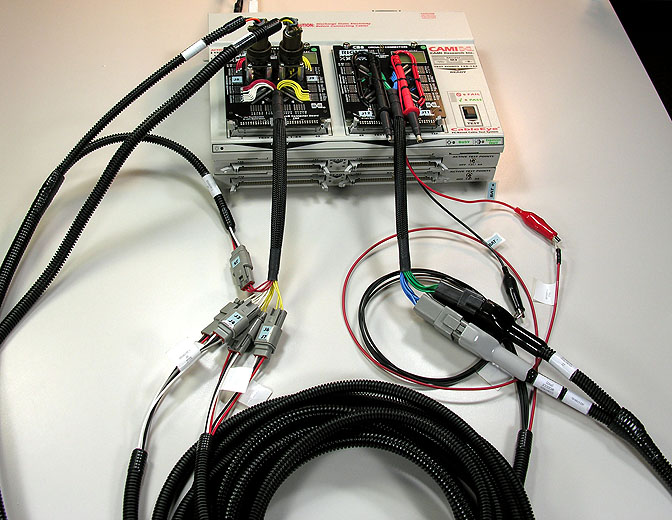

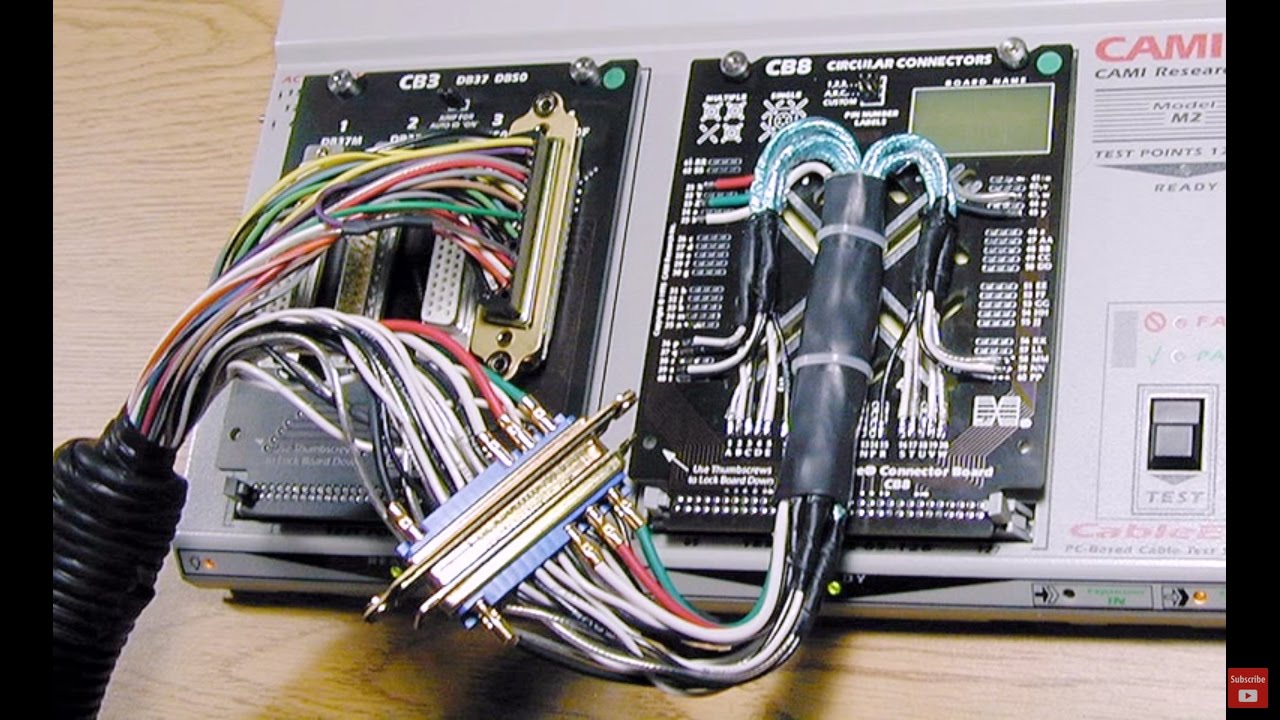

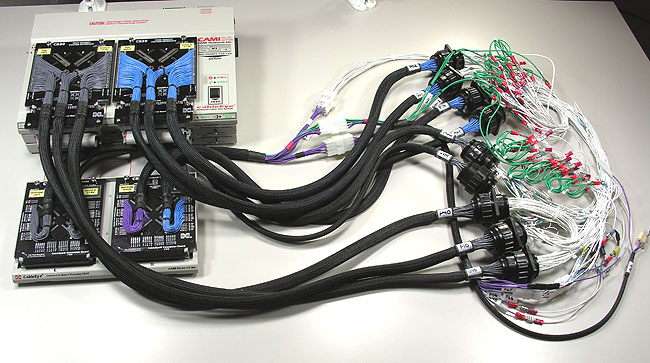

Harness Tester And Cable Tester From Cami Research

Read customer reviews find best sellers.

. If you have a working. The Cirris Systems CH2 tester fits our needs for flexibility and ease of use. The AVR can address the mux and test each line to see if its high.

We designed our testers with flexibility and adaptability in mind to meet a wide range of wire harness testing needs. Futuras Harness Testers offer state of the art wire harness testing. My initial design was quite simple.

Cable Wiring Harness Tester. After checking for opens shorts miswires and resistance limits the hipot module applies a user-selectable voltage from 10V to its models maximum voltage 2100Vdc1200Vac for the. Ad Always Get The Job Done With Reliable Electrical Solutions.

Connector housings need to have the correct wire loaded in the correct position and the best way to ensure this happens is to electronically. Our CableEye HVX Hipot Tester series permits expanded testing for insulation resistance and dielectric breakdown to meet the industry-standard A620 guidelines for cable and wire harness testing. Ad Use Dynalab NX Testers to test wire harnesses and cable assemblies.

Ad Browse discover thousands of brands. In conducting functional test on. The tester is located on either a harness board test table or standard table.

Insulation chosen for the aircraft wire harness design engineer select wire part number to use. The CH2 is a learning device. The system sets it as the standard for testing other harnesses.

I think that a computer program could be written which would give a picture on the screen showing which bits. Creating a Wire Harness with Harness Design Author. Learning Media Development LMD Subject.

Despite the increase in testing speed the continuity testing process has remained unchanged for several decades. Ive been given a task to design a wiring harness tester for automobiles. Floor-standing wire harness testers are built to stand on the floor.

I am involved in a wire harness manufacturing business that builds very large wire harnesses with many circuits that are usually branching out over a large area like a 4ft. If its high the wire is good to go. These features can be incorporated cost effectively through the use of switch pins that engage the components to verify their presence Fig.

Our Cable Wire Harness Testing Process. Each wire in a wire segment is then uniquely identified see Chapter 4 Wire. Usually we just buy a circuit tester which is very expensive and overkill for what we need which is just to see that a wire circuit is properly.

Or even larger build board. Switch pins look similar to spring probes. Using a 3D CAD system the wire paths are specified throughout the aircraft.

A Applicable harness design documentation b Materials c Design and construction d Identification of component e Workmanship. 1052010 92337 AM. The testers job is to test wiring harnesses which can contain upto 300 wires.

We can take an error-free harness and patch it in to the testing platform. Fixtures can also be designed to test for the presence of other connector and wire harness components such as secondary locks and clips. Our testers are fast accurate and easy to use.

Feed the wires 5V and connect them to multiplexers. For example todays standard tester can test 1000 wire points in 3 seconds whereas a 1990s tester needed 60 seconds. In addition connector disconnects will determine when a wire goes through a bulkhead.

But i dont think that making up circuits with LEDs is going to be a good answer. Benchtop wire harness testers are instruments that are portable and often include handles. After all of the wire or cable has been processed for assembly by our automated computer-controlled equipment the assembly process of a wire harness and cable assembly is a manual process.

For customers who need a new product design our engineering department can provide expert assistance with your wire harness or assembly design. Andrew also mentions the use of a computer for harness testing and i really think this is the way to go. Wire harness testers with computer board configuration are devices designed to be installed in a personal computer PC or used as a sub-card in a larger instrument.

That gets rid of the need to manually set each value and eliminates programming errors. Our engineering design capabilities include CAD-CAM drawings prototyping computerized testing and consulting on design options that increase quality and performance and lower production costs. Ad Lowest Price Guarantee - In Stock ISO 17025 6508 9001- Made in USA.

That way it would stop at the first incorrect wiring.

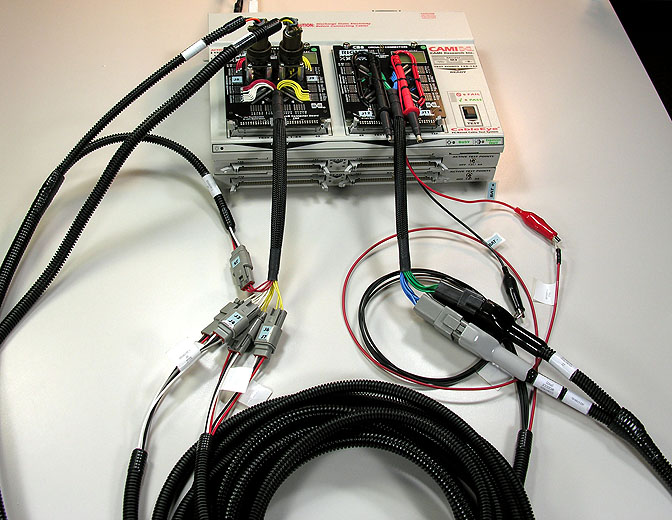

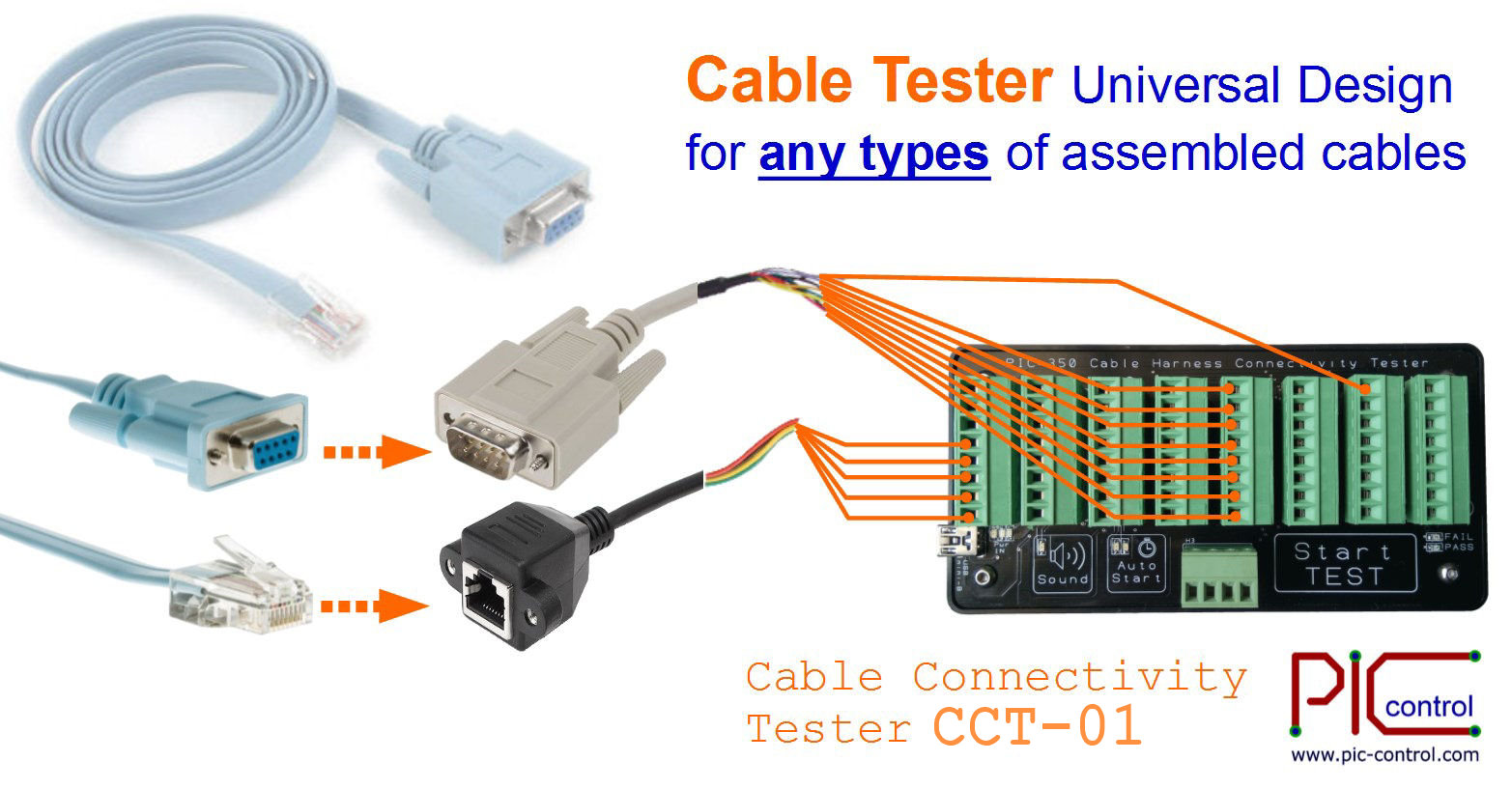

Cable Harness Tester Connectivity Checker Instrument Tool Kit

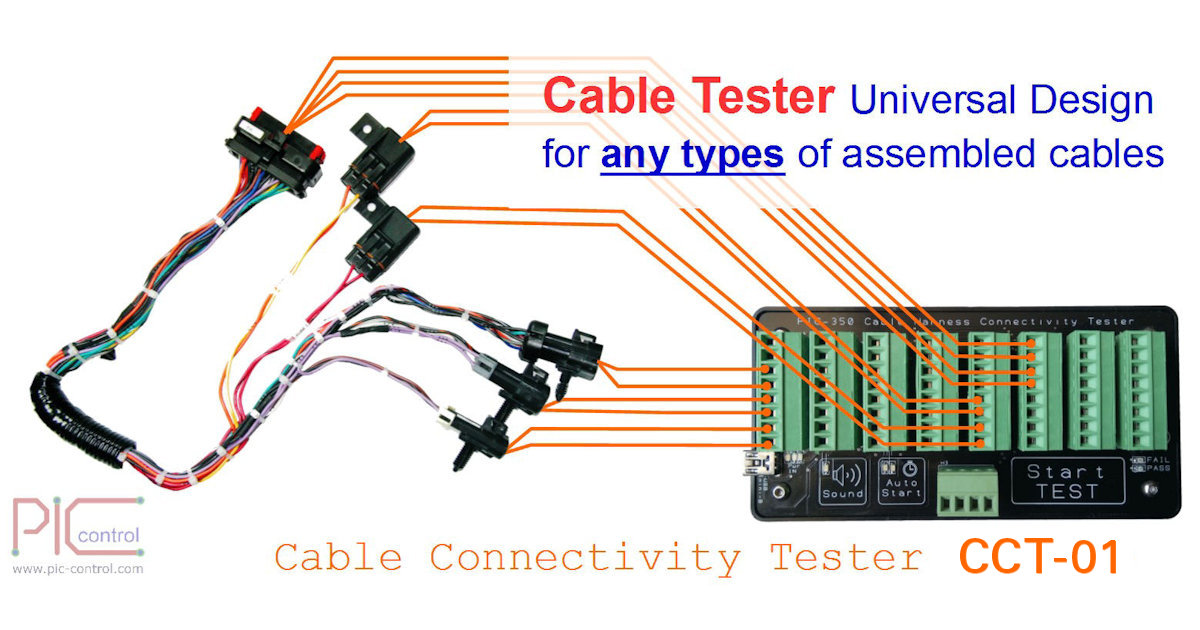

Wire Harness And Cable Testing Youtube

Cable Harness Tester Equipment Compare Wire Tester Tool

Harness Tester And Cable Tester From Cami Research

Cable Harness Tester Connectivity Checker Instrument Tool Kit

Harness Tester Board Hardware Share Pcbway

0 comments

Post a Comment